|

Ground Penetrating Radar Case Studies

GPR PS CASE STUDY #32

Sink Hole at Disney

Walt Disney’s Animal Kingdom park had a problem. There was a large pipe buried deep under ground that apparently had a substantial leak. The park maintenance personnel knew this because a large volume of water was entering the pipe and a small amount was leaving the pipe on the other end.

The Problem:

This pipe ran right through the animal park and could potentially cause a huge sink hole. The very expensive elephants and other animals could fall into one of these sink hole and potentially have to be put down.

The Solution:

Ben Cleary a ground penetrating radar expert was called in to see if he could find the broken pipe, so the park officials could repair it. A general area was mapped out where the pipe could have been damaged. GPR scanning was started using a 200MHz antenna.

The Result:

The pipe had broken and formed a huge sink hole just below the surface. The GPR data provided an excellent picture of where the pipe had been broken and the damage to the sub-surface.

The Conclusion:

Ground Penetrating Radar yielded the results needed to locate the sink hole. Collecting the GPR data was simple and upon reviewing the data, it was easy to identify the problem location.

For more information email: info@gprps.com

GPR PS Case Study #33

Pipe in the Wrong Place

In Tucson Arizona a new hotel was being built. The project manager of this new 120 room Marriott Hotel had a problem.

The Problem:

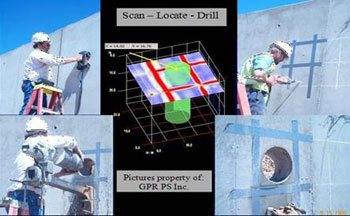

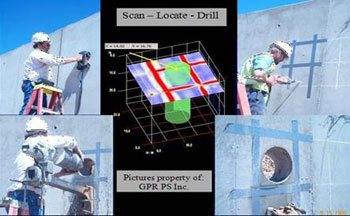

An eight inch pipe that was supposed to be on the out side of the building came up on the wrong side of the wall. The pipe needed to be moved to the outside wall by coring a hole through the concrete wall and redirecting the pipe through the outside wall. The structural engineer on the job requested no rebar was to be cut while drilling this hole and suggested Concrete X Ray.

The Solution:

Concrete X Ray is costly, time consuming and all work in the area must be evacuated. An alternative was suggested, Ground Penetrating Radar. GPR is a quick safe way to Scan Concrete. It use poses no threat to the operators when Scanning Concrete.

The Results:

The eight inch concrete wall was scanned using GPR. The rebar was laid out right on the surface of the concrete using duct tape. Then a cutting and coring company was called in the drill the hole. The hole was drilled successfully and the pipe was moved.

Photo Courtesy of GSSI Photo Courtesy of GSSI The Conclusion:

The project manager was satisfied that GPR was better than Concrete X Ray. It did not slow the job work down and the concrete cutter was able the move the pipe the other side of the wall.

For more information email: info@gprps.com

GPR PS Case Study # 35

Quality Check at DIA

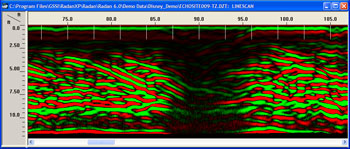

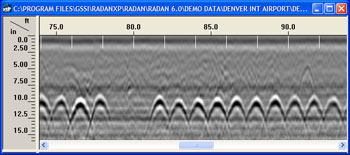

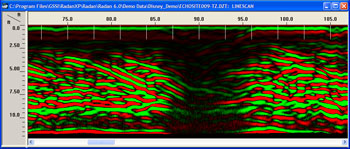

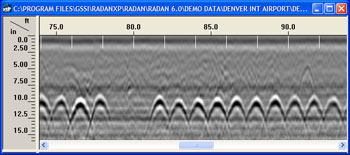

At the largest airport in the United Sates covering 53 square miles, a quality control question had arisen concerning the placement of 1.5 inch steel dowels that were placed in the concrete runways at Denver International Airport.

The Problem:

These 1.5 inch steel dowels were to be placed half way down in the concrete at 9” deep. The concern was they may have been placed at random heights which would not have conformed with the installation specifications. To chip up active runways to visually inspect the depth of the dowels was not an option.

The Solution:

Concrete X Ray or Ground Penetrating Radar seemed like a likely answer. Ben Cleary a GPR expert was called in to provide answers. GPR Scanning was performed on hundreds of feet of DIA runway.

The Results:

GPR showed the majority of rebar were placed according to the specs. There were a few places where rebar was placed an inch or two higher or lower and could be easily identified.

The Conclusion:

Ground Penetrating Radar saved a great deal of time and considerable expensive to Denver International Airport. The GPR Concrete Scanning presented results that were very useful the airport maintenance personnel.

For more information email: info@gprps.com

|